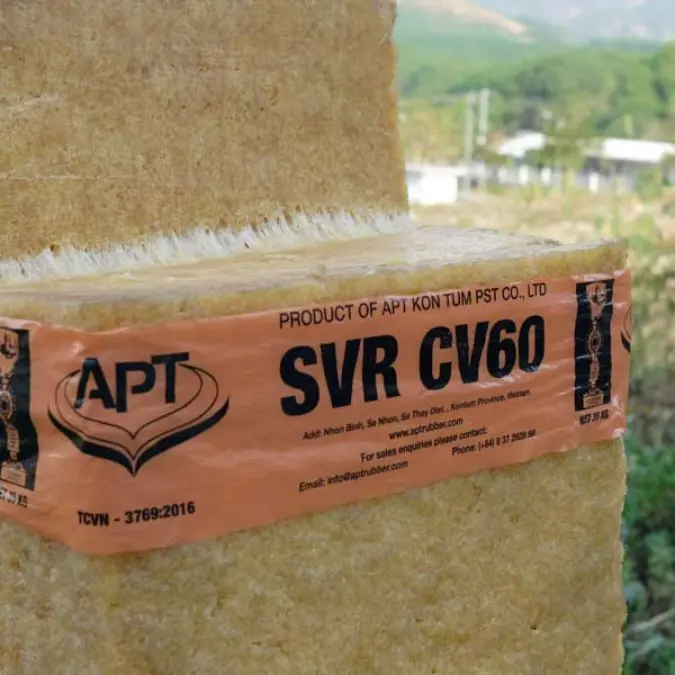

SVR CV60 (TSR CV60) Natural Rubber

Constant-viscosity natural rubber (Mooney 60±5), manufactured in Vietnam. EUDR-aligned supply available.

Product: SVR CV60 with Constant Viscosity (60±5) | EUDR Compliant

Status:

| Grade | Reference SVR CV60 Price (FOB) | Valid Until |

| SVR CV60 | From $2060 USD / MT* | 08/02/2026 |

*Note: Indicative price based on current market. Subject to volume available and APT’s final confirmation.

- 6-Month Guarantee on stable Mooney viscosity

- Direct sourcing from manufacturer

- Flexible Ordering for trial quantity and samples

Common Questions about SVR CV60

Is your rubber EUDR Compliant?

Yes. APT Rubber supports EUDR-aligned supply for SVR CV60. We provide traceability documentation and due-diligence information in line with EUDR requirements for shipments to the EU, supporting our customers’ compliance processes upon request.

Do you provide a Certificate of Analysis (COA)?

Yes, every shipment of our SVR CV60 is accompanied by a comprehensive Certificate of Analysis (COA). Our rubber is tested to meet Vietnamese Standard TCVN 3769:2016.

Does your SVR CV60 require premastication?

No. Because it is a Constant Viscosity (CV) grade, it saves your production line time and energy costs by eliminating the breakdown phase. It is ready for immediate compounding.

What is the difference between SVR CV60 and SVR 3L?

SVR CV60 is a Constant Viscosity rubber, meaning it maintains its softness and workability without needing pre-mastication. SVR 3L is graded for its light color. CV60 is superior for precision industrial adhesives and automotive parts where consistency is critical.

Why is SVR CV60 preferred for automotive parts and adhesive applications?

SVR CV60 is engineered for high-precision industries where material uniformity is critical. Its specific benefits include:

Automotive: Its superior resilience and consistent Mooney viscosity make it the top choice for vibration-damping parts, engine mounts, and windshield wiper blades.

Adhesives: The rubber provides high “green strength” (inherent strength before curing) and constant adhesiveness, ensuring a reliable bond in industrial tapes and chemical formulations.

Reduced Rejects: Uniform texture and minimal shrinkage during milling lead to significantly lower reject rates in extruded and molded rubber goods.

How do you ensure long-term quality and storage stability?

Natural rubber can “stiffen” during storage, but SVR CV60 is treated to prevent this by:

Viscosity Stabilization: We add a stabilization agent during the latex stage to ensure the rubber maintains its Mooney viscosity even after long-term storage or transoceanic shipping.

Storage Best Practices: To maintain these properties, we recommend storing the rubber in a cool, dry, and ventilated warehouse, away from direct sunlight and high humidity.

Quality Verification: Every batch is tested in labs certified.

Packaging & Shipping DAta

APT Rubber offers flexible packing solutions for our natural rubber products to meet diverse international shipping requirements. We provide standard 33.33kg and 35kg bales, wrapped in either Thin PE (dispersible) or Thick PE (strippable) film based on your processing needs.

Customers can choose between Loose Bale packing for maximum tonnage or Pallets for easier unloading. Our standard 20ft container load capacity ranges from 19.2 Metric Tons (MT) to 21 Metric Tons (MT).

| Specification | Details |

| Bale Weight | 33.33 kg or 35 kg |

| Bale Wrapping (PE) | Thin PE (Dispersible) or Thick PE (Strippable) |

| Packing Methods | Loose Bales (Floor Loaded) or Pallets |

| Container Capacity (20ft) | Pallet: 19.20 MT – 20.16 MT / Loose Bales: 21 MT |

Stabilize Your Production with Premium SVR CV60

Don’t let viscosity fluctuations slow down your mixing line. APT Rubber produces SVR CV60 (Constant Viscosity) specifically for manufacturers who require precision.

Unlike standard grades, our CV60 undergoes a rigorous viscosity-stabilization process using industry-standard agents to inhibit storage hardening. Our formulae guarantees a Mooney Viscosity of 60 (+/- 5) upon arrival at your factory.

Why Leading Manufacturers Choose APT Rubber:

- Guaranteed Stability: We guarantee minimum 6 months of Mooney viscosity stability. We understand shelf-life is your main concern, and unlike others, we commit to this claim.

- Energy Saving: Our soft, stable rubber requires minimal mastication, significantly reducing your electricity costs and mixing time.

- EUDR Ready: We provide full traceability data (geolocation) for every container, ensuring your products are safe for the European market.

- 25+ Years of Expertise: Established in 1998, we have over two decades of experience in processing natural rubber.

- Global Trust: Our SVR CV60 is currently trusted by buyers in USA, India, Korea, Japan, Germany and Malaysia.

- Direct Sourcing: Buy directly from our Vietnam factory to eliminate middleman margins.

- 2 FACTORIES

Located in Dong Nai and Quang Ngai Province, Vietnam

- 40,000 MT/YEAR

Wet latex line – 20,000 MT

Cup lump line – 20,000 MT

- QUALITY

TCVN 3769:2016

ISO 19001:2015

- GREEN

ISO 14001:2015

EUDR Compliance

Technical Data (TCVN 3769:2016)

Our SVR CV60 is rigorously tested to meet or exceed national standards.

| Parameter | Limit | APT Rubber Result |

| Mooney Viscosity (ML 1+4, 100°C) | 60 ± 5 | Strictly Controlled |

| Dirt Content (max % wt) | 0.02 | ≤ 0.02% (High Purity) |

| Ash Content (max % wt) | 0.40 | ≤ 0.40% |

| Nitrogen Content (max % wt) | 0.60 | ≤ 0.60% |

| Volatile Matter (max % wt) | 0.80 | ≤ 0.80% |

| Plasticity Retention (PRI) (min) | 60 | > 60 (High Aging Resistance) |

| Lovibond Color | – | Yellow |

Evaluate the best grade for your technical and cost targets

💡 Customization Note: While strictly adhering to TCVN 3769:2016, we offer custom blending services to adjust finished product parameters to your specific manufacturing requirements. Contact us to discuss your technical profile.

Our Quality Control Process

From the rubber farm to the final bale, we monitor 5 critical control points to ensure our “6-Month Stability” guarantee.

This grade is manufactured in our owned Vietnam natural rubber manufacturing facilities under ISO-aligned quality systems.

Latex Reception: Screening for DRC and Ammonia content.

Viscosity Stabilization: Precise dosing of stabilizers agent.

Mechanical Processing: Crumbing and washing to remove dirt (0.02% limit).

Drying: Controlled temperature to maintain plasticity (PRI > 60).

Lab Testing: Every pallet is tested for Mooney Viscosity before packing.

Our natural rubber processing production line is supplied and maintained periodically by Quang Trung Mechanical Co., Ltd., a reputable company in the mechanical industry, manufacturing production lines, laboratory equipments and waste water treatment systems in Vietnam rubber industry.

Audited under ISO 9001 & ISO 14001 systems

APPLICATIONS

- Pressure-sensitive adhesives (PSA)

- Industrial glues (High Tack)

- Packaging & wrapping materials

- Tire treads & sidewalls

- Vibration-dampening pads

- Inner tubes & Engine mounts

- Conveyor belt covers

- Gaskets & Heavy-duty seals

- Industrial Hoses

- Table tennis rackets

- High-grade rubber bands

- Sports equipment

👉Explore Related SVR Grades

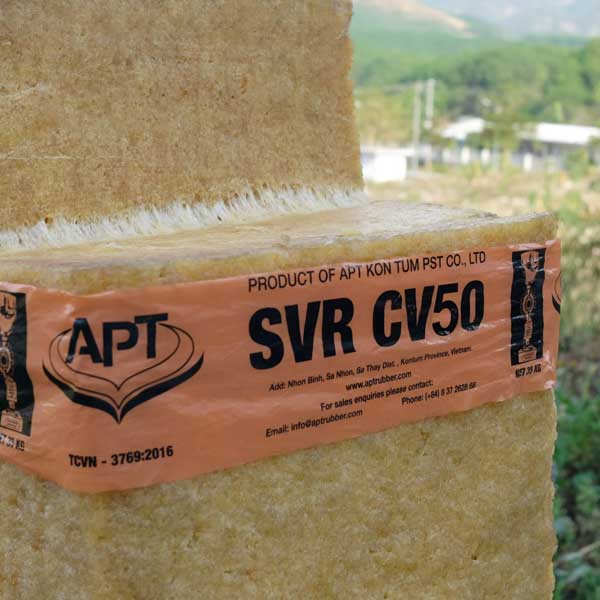

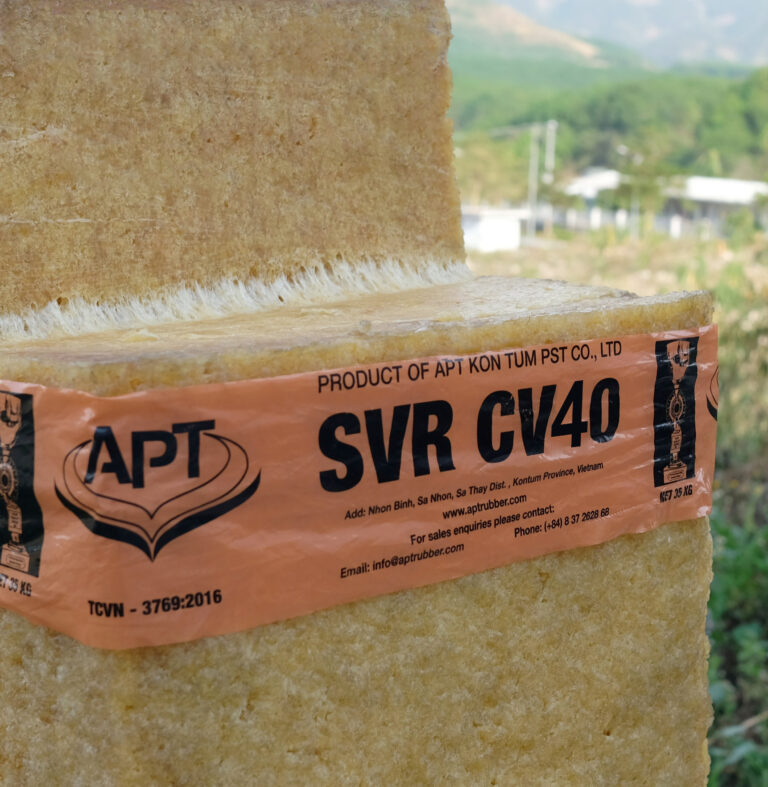

Constant Viscosity (50±5). A softer alternative to CV60, offering excellent flow and reduced energy consumption during mixing.

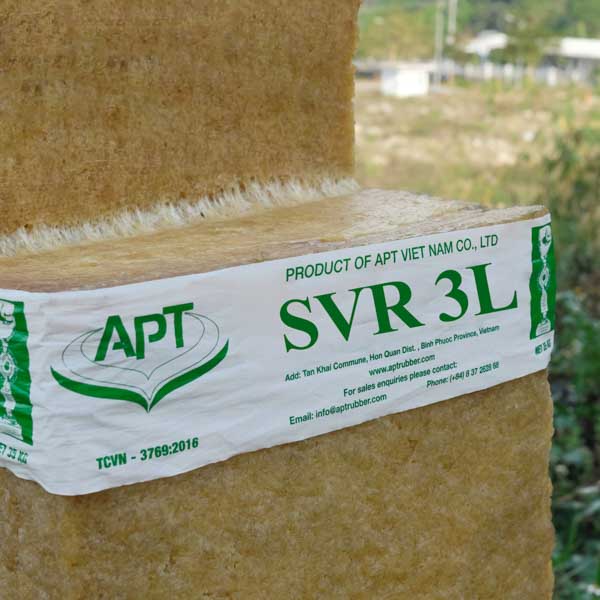

Light-colored, high-purity rubber with low dirt content (0.03%). The industry standard for adhesives, medical parts, and colored products.

✅ EUDR Compliant.