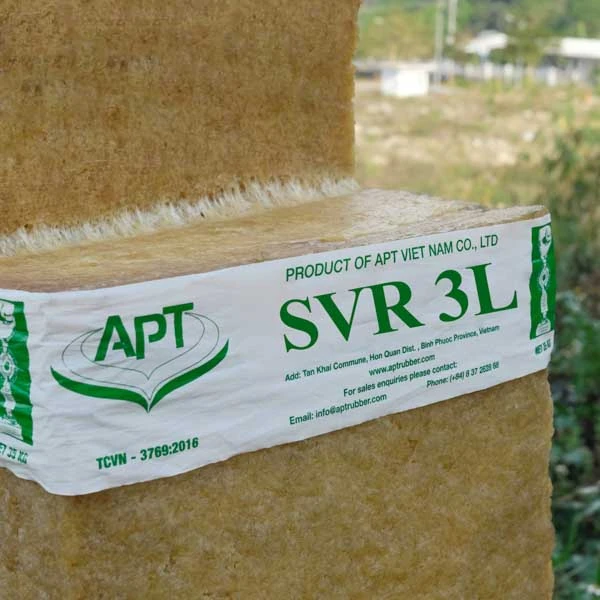

SVR 3L (TSR 3l) Natural Rubber

SVR 3L is a light color, high-purity technically specified natural rubber, manufactured in Vietnam. EUDR-aligned supply available upon request.

Product: SVR 3L with light lovibond color | EUDR Compliant

Status:

| Grade | Reference SVR 3L Price (FOB) | Valid Until |

| SVR 3L | From $2190 USD / MT* | 08/03/2026 |

*Note: Indicative price based on current market. Subject to volume available and APT’s final confirmation.

- Light color: Lovibond color from 4.5 guaranteed

- Direct sourcing from manufacturer

- Flexible Ordering for trial quantity and samples

Common Questions about SVR 3L

Is your rubber EUDR Compliant?

Yes. APT Rubber supports EUDR-aligned supply for SVR 3L upon request. Traceability documentation and due-diligence information can be provided for EU-bound shipments in line with applicable requirements.

What is the closest replacement for SVR 3L, and why?

The most suitable alternative to SVR 3L depends on which performance or commercial factor is prioritized:

- SVR 3L is preferred when appearance quality and material cleanliness are critical to the finished product.

- SVR 5 is commonly selected for cost-sensitive applications where a darker appearance and higher impurity tolerance are acceptable.

- SVR CV60 may be considered when processing stability and consistency are prioritized over visual appearance, due to its controlled Mooney viscosity.

- Mixtures of SVR 3L are used in certain markets, such as China, as a cost-optimized alternative for applications with similar technical requirements.

Final material selection should always be confirmed through formulation and processing trials.

What is the difference between SVR 3L and SVR CV grades?

SVR 3L is specified based on cleanliness and impurity limits, while SVR CV grades are produced with controlled Mooney viscosity. SVR 3L does not have viscosity control.

What determines the color of SVR 3L?

The color of SVR 3L is primarily influenced by raw material quality (field latex cleanliness) and processing control, particularly the removal of dirt, bark particles, and non-rubber constituents during production.

SVR 3L is produced to stricter impurity limits than general-purpose SVR grades, which results in better visual cleanliness and a more uniform appearance, as reflected in its Lovibond color index requirement under TCVN 3769:2016.

Will the color of SVR 3L change over time?

Yes. Like all natural rubber, SVR 3L will gradually darken over time due to natural oxidative aging.

Color change may occur during storage as a result of:

- Exposure to oxygen

- Heat and sunlight

- Extended storage duration

This darkening is a natural characteristic of natural rubber and does not necessarily indicate deterioration of key physical properties if storage conditions are properly maintained.

Why is SVR 3L selected for appearance-sensitive products?

Due to its light color, lower dirt content and controlled impurity levels, SVR 3L is commonly used where visual uniformity and surface quality are important.

How should SVR 3L be stored to help maintain a lighter appearance?

To help preserve the visual cleanliness and slow color darkening, SVR 3L should be stored:

- In a cool, dry, and well-ventilated area

- Away from direct sunlight and heat sources

- Protected from moisture, rain, and water contact

- Away from strong oxidizing agents and chemicals

These storage practices align with standard natural rubber handling guidelines and help minimize premature aging and discoloration.

Packaging & Shipping DAta

APT Rubber offers flexible packing solutions for our natural rubber products to meet diverse international shipping requirements. We provide standard 33.33kg and 35kg bales, wrapped in either Thin PE (dispersible) or Thick PE (strippable) film based on your processing needs.

Customers can choose between Loose Bale packing for maximum tonnage or Pallets for easier unloading. Our standard 20ft container load capacity ranges from 19.2 Metric Tons (MT) to 21 Metric Tons (MT).

| Specification | Details |

| Bale Weight | 33.33 kg or 35 kg |

| Bale Wrapping (PE) | Thin PE (Dispersible) or Thick PE (Strippable) |

| Packing Methods | Loose Bales (Floor Loaded) or Pallets |

| Container Capacity (20ft) | Pallet: 19.20 MT – 20.16 MT / Loose Bales: 21 MT |

Stabilize Your Production with Light-Color SVR 3L

Don’t let raw material contamination and color inconsistency disrupt your finished product quality.

APT Rubber produces SVR 3L specifically for manufacturers who require controlled impurity levels, visual cleanliness, and consistent appearance in their rubber compounds.

Unlike general-purpose grades, SVR 3L is processed with stricter cleanliness control during raw material selection and mechanical processing, helping reduce surface defects and visual variation in appearance-sensitive rubber goods.

Why Leading Manufacturers Choose to Buy SVR 3L from APT Rubber:

- Controlled Visual Cleanliness: SVR 3L is produced to tighter impurity limits under TCVN 3769:2016, supporting more uniform appearance compared with general-purpose SVR grades.

- Reduced Color Variation Risk: Careful raw material screening and washing processes help minimize dirt and non-rubber constituents that can affect visual quality.

- Suitable for Appearance-Sensitive Products: Commonly selected for rubber goods where surface quality and visual consistency are important considerations.

- EUDR-Ready (Upon Request): We can provide traceability and due-diligence documentation for EUDR-aligned shipments to the EU, subject to order scope and destination.

- 25+ Years of Manufacturing Experience: Established in 1998, APT Rubber has long-term experience in producing technically specified natural rubber grades.

- Direct from Manufacturer: Supplied directly from our Vietnam factories, ensuring controlled production and transparent quality management.

Technical Data (TCVN 3769:2016)

- Natural supplied by APT Rubber is tested according to TCVN 3769:2016, equivalent to ISO 17001 standards.

- Actual results are provided in the Certificate of Analysis (COA) for each shipment

| Parameter | Limit | APT Rubber Result |

|---|---|---|

| Dirt Content (max % wt) | 0.03 | ≤ 0.03% (Controlled Cleanliness) |

| Ash Content (max % wt) | 0.50 | ≤ 0.50% |

| Nitrogen Content (max % wt) | 0.60 | ≤ 0.60% |

| Volatile Matter (max % wt) | 0.80 | ≤ 0.80% |

| Initial Plasticity (P₀, min) | 35 | ≥ 35 |

| Plasticity Retention Index (PRI, min) | 60 | ≥ 60 |

| Lovibond Color Index (max) | 6 | From 4.0 to 6.0 |

Evaluate the best grade for your technical and cost targets

Our Quality Control Process

From the rubber farm to the final bale, we monitor 5 critical control points to ensure consistent cleanliness, controlled impurity levels, and compliance with TCVN 3769:2016 for SVR 3L.

This grade is manufactured in our owned Vietnam natural rubber manufacturing facilities under ISO-aligned quality systems.

- Latex Reception: Screening of incoming field latex to verify raw material quality and remove visible contaminants prior to processing.

- Coagulation & Pre-Processing: Controlled coagulation and handling to minimize contamination and preserve the natural properties of the rubber.

- Mechanical Processing: Crumbing and repeated washing to reduce dirt and non-rubber constituents in line with SVR 3L impurity limits defined under TCVN 3769:2016.

- Drying: Controlled drying temperature and duration to maintain stable plasticity and prevent premature thermal or oxidative degradation.

- Laboratory Testing: Each production lot is tested for key quality parameters including dirt content, ash content, nitrogen content, volatile matter, and plasticity (P₀ and PRI) prior to packing.

Our natural rubber processing production line is supplied and maintained periodically by Quang Trung Mechanical Co., Ltd., a reputable company in the mechanical industry, manufacturing production lines, laboratory equipments and waste water treatment systems in Vietnam rubber industry.

Audited under ISO 9001 & ISO 14001 systems

APPLICATIONS

SVR 3L is selected for applications where material cleanliness, controlled impurity levels, and visual uniformity are important.

Unlike constant-viscosity grades, SVR 3L is not specified for Mooney control, but is widely used in products where appearance consistency and low contamination risk are required under standard rubber processing conditions.

Application suitability depends on formulation and end-use requirements.

- Molded technical rubber components

- Rubber parts requiring low dirt content

- Precision rubber items with appearance sensitivity

- Light-appearance rubber goods

- Rubber bands, threads, and similar products

- Consumer rubber items with visual requirements

- Industrial molded rubber parts

- General-purpose rubber sheets and profiles

- Rubber components under non-critical mechanical conditions

- Sporting and leisure rubber products

- Household rubber items

- Specialty rubber goods requiring cleaner raw material

👉Explore Related SVR Grades

A more cost-competitive alternative to SVR 3L, ideal for applications where color is not a primary concern but reliable mechanical properties are required under standard processing conditions

Constant Viscosity (60±5): An alternative solution with stabilized viscosity, contributing to lower energy usage during the compounding and mastication stages.

✅ EUDR Compliant.

This SVR 3L natural rubber compound is meticulously blended from SVR 3L and SBR 1502. It is widely recognized and preferred by manufacturers across the Chinese market.

✅ EUDR Compliant.