At the beginning of 2022, APT Rubber successfully finished the first stage of building the rubber testing laboratory that satisfies the requirements of VILAS (ISO/IEC 17025:2005).

Qualified Staff Members

Staff members constantly review technical standard of natural rubber SVR, renovate quality control system according to high industry standards, train associated departments to follow procedure with actual manufacturing concepts.

Modern Machinery System

The system offers a broad range of services such as exanimating technical components of rubber raw materials, testing Natural Rubber Products according to National Standard TCVN 3769:2016 including initial ductility (Po), plasticity retention index (PRI), Mooney viscosity,…

Strict Testing Process

High-precision rubber testing equipment and machinery:

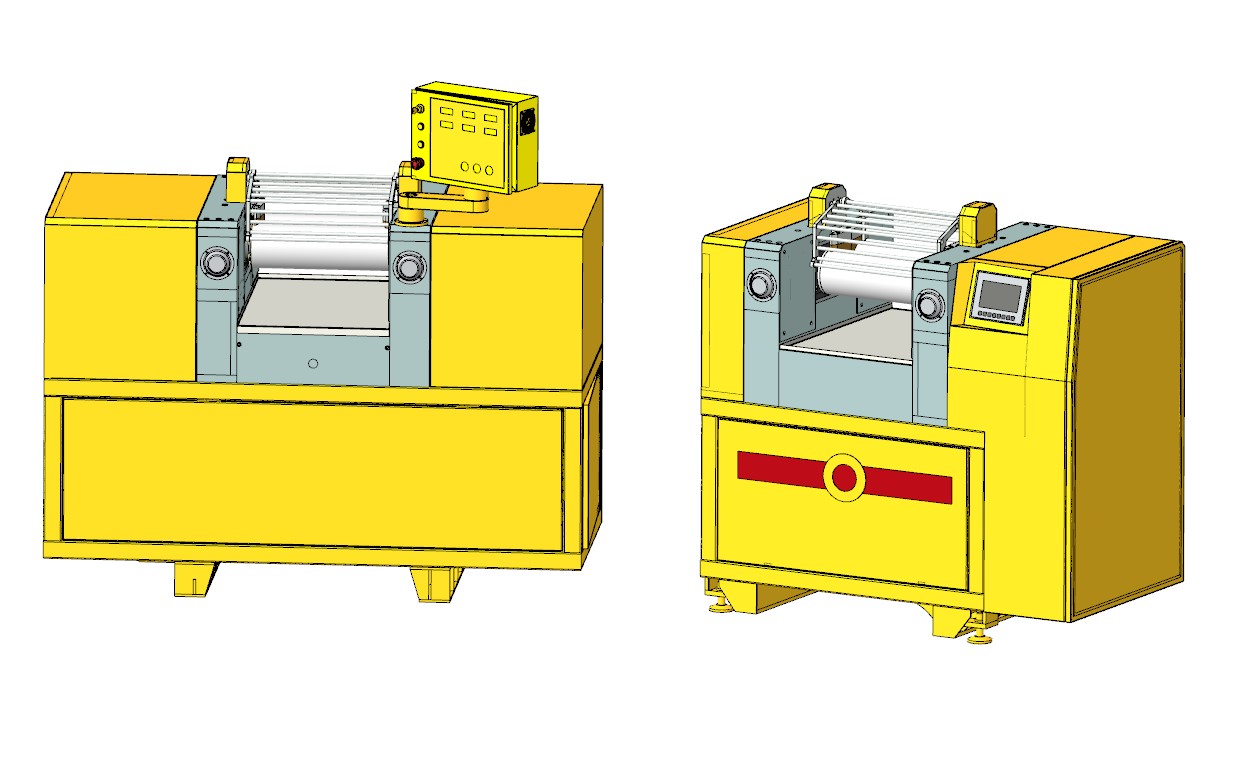

1. Rubber Rolling Machine: LT twin shaft mill consists of two rollers made of steel with hard chrome plating, both running coils have variable speed and are set by the end user by a touch screen. Rubber Rolling Machine is manufactured by QUANG TRUNG CO., LTD which is a originating partnership of APT Group established in 1993.

2. Aging Oven: Automatic PID temperature controller with accuracy of ± 0.1 ℃.

STANDARD: ISO 2930, ASTM D 3194

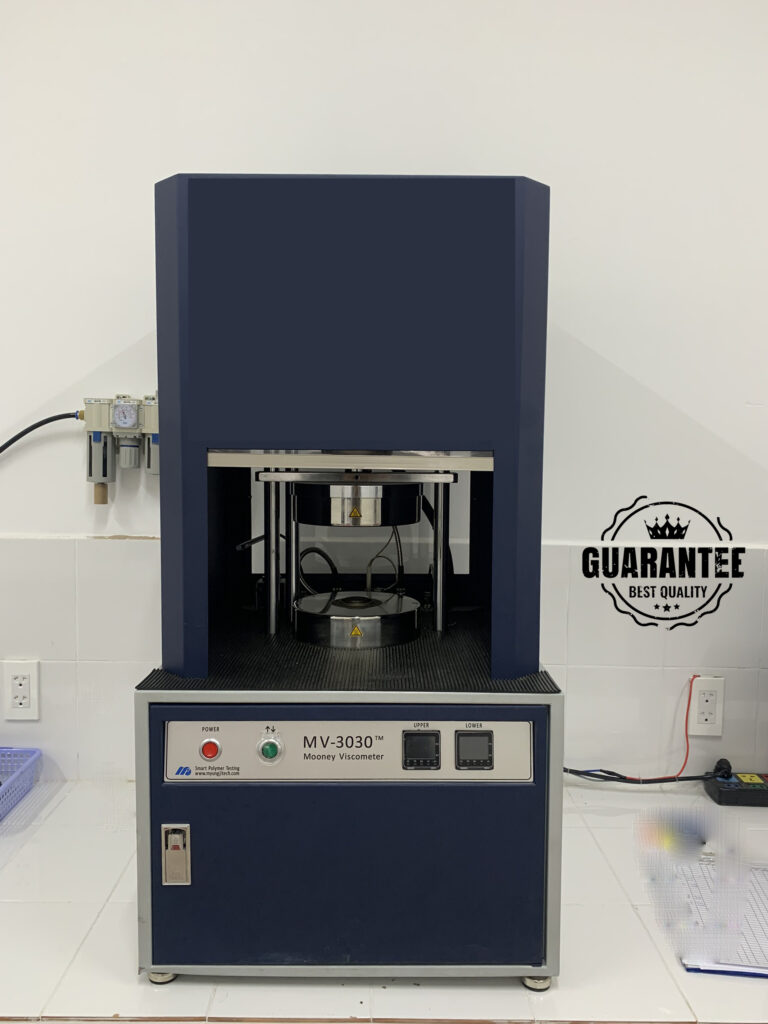

3. Mooney Viscometer: This is one of the core instruments for measuring viscous flow of polymer and master batch testing.

STANDARD: ASTM D1646, KS M ISO 289

4. Rapid Plastimeter: Fully automatic calibration and offset adjustment. The results are stable, accurate to the results of the calibrators.

STANDARD: BS 903: Pt A59 : section A59.1 : 1997, ISO 2007: 2018.

The investment in cutting edge equipment clearly shows the international orientation, focusing on adapting to changing consumer needs and industry trends, Reaching New Customers in Different Markets, especially with EU purchasers.

In parallel with the completion of the rubber testing laboratory APT Rubber continues to renovate production line, embed quality practices in routine processes, increase responsiveness for any future demand in Natural Rubber Products and always opportunities to improve market position in the rubber industry in Vietnam in particular and the world in general.