WHAT IS SVR 5 NATURAL RUBBER?

DEFINITION

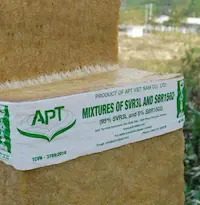

SVR 5 (equivalent to technical rubber TSR 5) is a high quality natural rubber, in the form of crumb rubber, common in preliminarily processed rubber and produced by many factories in Vietnam.

SVR 5 has darker color than SVR 3L. The main source of raw materials for SVR 5 natural rubber production is latex. SVR 5 main features are

- High level of purity

- High elasticity and elongation

- Good aging resistance

- Bright color (although color is darker than SVR 3L but SVR 5 is still considered as brighter than other types of SVR rubber)

- Cheaper than SVR 3L

APPLICATIONS

In order to meet the products of SVR 5 grade, it must satisfy important characteristics such as Po, color (Lovibond), dirt content, storage … in standard TCVN 3769: 2016.

As a result from high PO parameter characteristics (PO> 30), it’s products are applied to products that require high elasticity as well as high abrasion resistance. Common applications of SVR 5 natural rubber include car tires, belts, power cables, bicycle guts, washers, other rubber parts in cars, etc, for instance.

It is also used in products that need light color high quality straps, cables, shoe soles, medical products, electronics industry, high quality products in the medical industry…

- 2 FACTORIES

Located in Binh Phuoc Province and Kontum Province, Vietnam

- 40,000 MT/YEAR

SVR3L – 20,000/y

SVR10 – 20,000/y

- QUALITY

All products meet TCVN 3769:2016 standard

- GREEN

Advanced wastewater treatment technology

QUALITY OF SVR 5 NATURAL RUBBER ACCORDING TO TCVN 3769:2016

Quality specifications according to TCVN3769:2016 standard is described as below:

- Dirt content (max% wt), retained on 45 micron sieve: 0,05

- Ash content (max % wt): 0,60

- Nitrogen content (max % wt): 0,60

- Volatile matter (max % wt): 0,80

- Initial plasticity ( Po ) (min): 30 – 41

- Plasticity retention index (PRI) (min): 60

There is another rank of SVR 5 called SVR 5S, which characterised P0 from 30 to 41.

PRODUCTION PROCESS OF APT RUBBER

Latex of garden plants according to Vietnamese standards (TCVN: 3769) is what SVR5 is produced entirely from. Firstly, it is preserved by ammonia or sodium sulfite. Secondly, the rubber is then coagulated with formic acid, followed by shredding by passing through a rolling mill, washing system and hash. Finally, after the crumb rubber is dried, it will be compressed into blocks and packed in polyethylene bags. At this point, It has a light colored rubber with a low content of dirt and odorless.

In fact, our SVR 5 rubber processing production line is supplied and maintained periodically by Quang Trung Mechanical Co., Ltd., a reputable company in the mechanical industry, manufacturing production lines and water treatment systems. waste in Vietnam rubber industry.

More information about Quang Trung Mechanical Co., Ltd: Click here

why should you buy svr 5 from apt rubber?

The answers are pretty concrete:

- Strong commitment on quality: but with reasonable price because we are manufacturer.

- 25+ years of expertise: established since 1998, we have more than 25 years of experiences in processing natural rubber.

- Export markets: Our SVR 5 range has been welcomed in global markets such as USA, India, Korea, Malaysia…

You can also find other high quality natural rubber at APT Rubber. Explore our other range of natural rubber as below: